SPEAK TO THE PROBLEMS

(SHORT NOTES FROM PROBLEM SOLVING SKILLS:

THE TOOLS

CATWOE

Developing a Robust Problem Definition

CATWOE stands for:

Customers

Who are they, and how does the issue

affect them?

Actors Who is involved in

the situation? Who will be involved in implementing solutions? And what will

impact their success?

Transformation Process What

processes or systems are affected by the issue?

World View What is the big

picture? And what are the wider impacts of the issue?

Owner Who owns the

process or situation you are investigating? And what role will they play in the

solution?

Environmental Constraints What

are the constraints and limitations that will impact the solution and its

success?

The FOCUS Model

A Simple, Efficient Problem-Solving Approach

Identifying problems is like harvesting fruit.

About

the Model

The FOCUS* Model is a structured approach to Total

Quality Management (TQM), and it is widely used in the health care industry.

The model is helpful because it uses a team-based

approach to problem solving and to business-process improvement, and this

makes it particularly useful for solving cross-departmental process issues. Also, it encourages people to rely on

objective data rather than on personal opinions, and this improves the quality

of the outcome.

It has five steps:

Find the problem.

Organize a team.

Clarify the problem.

Understand the problem.

Select a solution.

Applying the FOCUS Model

Step 1: Find the Problem

· identify a process that needs to be improved

· follow the Pareto Principle, where 80 percent of issues come from 20

percent of problems.

· Start with a simple problem to get the team up to speed with the FOCUS

method.

· If you have several problems that need attention, list them all and use

Pareto Analysis, Decision Matrix Analysis, or Paired Comparison Analysis to

decide which problem to address first.

Step 2: Organize a Team

· assemble a team to address the problem

· bring together team members from a range of disciplines – this will give

you a broad range of skills, perspectives, and experience to draw on

· Select team members who are familiar with the issue or process in hand,

and who have a stake in its resolution

· If your first choice of team member isn't available, try to appoint

someone close to them, or have another team member use tools like Perceptual

Positioning and Rolestorming to see the issue from their point of view.

· a diverse team is more likely to find a creative solution than a group of

people with the same outlook.

Step 3: Clarify the Problem

· define the problem clearly and concisely

· the key to success is to break it down into "sushi-sized"

pieces that can be analyzed and solved more easily

· Use the Drill Down technique to break big problems down into their

component parts. You can also use the 5

Whys Technique, Cause and Effect Analysis, and Root Cause Analysis to get to

the bottom of a problem.

· Record the details in a problem statement, which will then serve as the

focal point for the rest of the exercise (CATWOE can help you do this effectively.)

· The problem statement must be objective.

· be on guard against "factoids" – statements that appear to be

facts, but that are really opinions that have come to be accepted as fact.

Step 4: Understand the Problem

· gather data about the problem to understand it more fully.

· Dedicate plenty of time to this stage, as this is where you will identify

the fundamental steps in the process that, when changed, will bring about the

biggest improvement.

· Consider what you know about the problem. Has anyone else tried to fix a

similar problem before? If so, what happened, and what can you learn from this?

· Use a Flow Chart or Swim Lane Diagram to organize and visualize each

step; this can help you discover the stage at which the problem is happening.

· And try to identify any bottlenecks or failures in the process that could

be causing problems.

· As you develop your understanding, potential solutions to the problem may

become apparent.

· Beware of jumping to "obvious" conclusions – these could

overlook important parts of the problem, and could create a whole new process

that fails to solve the problem.

· Generate as many possible solutions as you can through normal structured

thinking, brainstorming, reverse brainstorming, and Provocation. Don't criticize ideas initially – just come up

with lots of possible ideas to explore.

Step 5: Select a Solution

· select a solution

· Use appropriate decision-making techniques to select the most viable

option. Decision Trees, Paired

Comparison Analysis, and Decision Matrix Analysis are all useful tools for

evaluating your options.

· Once you've selected an idea, use tools such as Risk Analysis, "What

If" Analysis, and the Futures Wheel to think about the possible

consequences of moving ahead, and make a well-considered go/no-go decision to

decide whether or not you should run the project.

Note:

People commonly use the FOCUS Model in conjunction

with the Plan-Do-Check-Act cycle.

Key

Points

1.

The FOCUS Model is a simple quality-improvement tool

commonly used in the health care industry.

2.

The five steps in FOCUS are as follows:

Find the problem.

Organize a team.

Clarify the problem.

Understand the problem.

Select a solution.

3.

People often use the FOCUS Model in conjunction with

the Plan-Do-Check-Act cycle, which allows teams to implement their solution in

a controlled way.

5 Whys

Getting to the Root of a Problem Quickly

How

to use the 5 Whys technique, with James Manktelow & Amy Carlson.

To solve it properly, you need to drill down through

the symptoms to the underlying cause. This article looks at Sakichi Toyoda's 5 Whys

technique – a simple but powerful tool for quickly uncovering the root of a

problem, so that you can deal with it once and for all.

About

the Tool

Sakichi Toyoda, one of the fathers of the Japanese

industrial revolution, developed the 5 Whys technique in the 1930s. He was an industrialist, inventor and founder

of Toyota Industries. His technique

became popular in the 1970s and Toyota still uses it to solve problems today.

Toyota has a "go and see" philosophy. This means that its decision making is based

upon an in-depth understanding of the processes and conditions on the shop

floor, rather than reflecting what someone in a boardroom thinks might be

happening.

The 5 Whys technique is true to this tradition, and

it is most effective when the answers come from people who have hands-on

experience of the process being examined. It is remarkably simple: when a problem

occurs, you uncover its nature and source by asking "why" no fewer

than five times.

When

to Use the 5 Whys

You can use the 5 Whys in troubleshooting, quality

improvement and problem solving, but it is best for simple or moderately

difficult problems.

The simplicity of the 5 Whys tool gives it great

flexibility, too, and it combines well with other methods and techniques. It is often associated with lean manufacturing

(also part of the Toyota Production System), where it is used to identify and

eliminate wasteful practices. It is also

used in the analysis phase of the Six Sigma quality improvement methodology.

How

to Use the 5 Whys

The 5 Whys is a simple, practical tool that is very

easy to use. When a problem arises, simply keep asking the question

"why" until you reach the underlying source of the problem, and until

a robust counter-measure becomes apparent.

Note:

1.

The 5 Whys uses "counter-measures," rather

than solutions. A counter-measure is an

action or set of actions that seeks to prevent the problem arising again, while

a solution just seeks to deal with the situation. As such, counter-measures are

more robust, and are more likely to prevent the problem from recurring.

2.

Each time you ask "why," look for an

answer that is grounded in fact: it must be an account of things that have

actually happened – not events that might have happened.

3.

Keep asking "why" until you feel confident

that you have identified the root cause and can go no further.

Key

Points

1.

The 5 Whys strategy is an easy to use, effective

tool for uncovering the root of a problem. You can use it in troubleshooting,

problem solving and quality improvement initiatives.

2.

Start with a problem and ask "why" it is

occurring. Make sure that your answer is grounded in fact, then ask

"why" again. Continue the process until you reach the root cause of

the problem, and you can identify a counter-measure that prevents it recurring.

3.

Bear in mind that this questioning process is best

suited to simple to moderately-difficult problems. Complex problems may benefit

from a more detailed approach (although using 5 Whys will still give you useful

insights.)

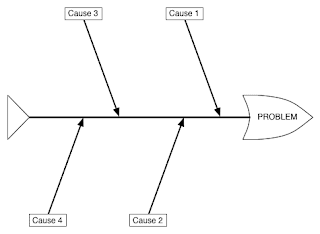

Cause and Effect Analysis

Identifying the Likely Causes of Problems

(Also known as Cause and Effect Diagrams, Fishbone

Diagrams, Ishikawa Diagrams, Herringbone Diagrams, and Fishikawa Diagrams.)

Cause & Effect Diagrams

Find all possible problems.

When you have a serious problem, it's important to

explore all of the things that could cause it, before you start to think about

a solution. That way you can solve the

problem completely, first time round, rather than just addressing part of it

and having the problem run on and on.

Cause and Effect Analysis gives you a useful way of

doing this. This diagram-based

technique, which combines Brainstorming with a type of Mind Map, pushes you to

consider all possible causes of a problem, rather than just the ones that are

most obvious.

About

the Tool

Cause and Effect Analysis was devised by professor

Kaoru Ishikawa, a pioneer of quality management, in the 1960s. The technique was then published in his 1990

book, "Introduction to Quality Control." The diagrams that you create with Cause and

Effect Analysis are known as Ishikawa Diagrams or Fishbone Diagrams (because a

completed diagram can look like the skeleton of a fish). Cause and Effect Analysis was originally

developed as a quality control tool, but you can use the technique just as well

in other ways.

How

to Use the Tool

Step 1: Identify the Problem

· write down the exact problem. Where

appropriate, identify who is involved, what the problem is, and when and where

it occurs.

· write the problem in a box on the left-hand side of a large sheet of

paper, and draw a line across the paper horizontally from the box. This

arrangement, looking like the head and spine of a fish, gives you space to

develop ideas.

Figure 1 – Cause and Effect Analysis Example

Tip 1: Some people prefer to write

the problem on the right-hand side of the piece of paper, and develop ideas in

the space to the left. Use whichever approach you feel most comfortable with.

Tip 2: It's important to define

your problem correctly. CATWOE can help you do this – this asks you to look at

the problem from the perspective of Customers, Actors in the process, the

Transformation process, the overall World view, the process Owner, and

Environmental constraints.

Step 2: Work Out the Major Factors Involved

· identify the factors that may be part of the problem. These may be

systems, equipment, materials, external forces, people involved with the

problem, and so on.

· Try to draw out as many of these as possible. As a starting point, you

can use models such as the McKinsey 7S Framework (which offers you Strategy,

Structure, Systems, Shared values, Skills, Style and Staff as factors that you

can consider) or the 4Ps of Marketing (which offers Product, Place, Price, and

Promotion as possible factors).

· Brainstorm any other factors that may affect the situation.

Step 3: Identify Possible Causes

· brainstorm possible causes of the problem that may be related to the

factor.

· Where a cause is large or complex, then it may be best to break it down

into sub-causes. Show these as lines

coming off each cause line.

Step 4: Analyze Your Diagram

· Depending on the complexity and importance of the problem, you can now

investigate the most likely causes further.

Tip: A useful way to use Cause and

Effect Analysis with a team is to write all of the possible causes of the

problem down on sticky notes. You can then group similar ones together on the

diagram.

This

approach is sometimes called CEDAC (Cause and Effect Diagram with Additional

Cards) and was developed by Dr. Ryuji Fukuda, a Japanese expert on continuous

improvement.

Key

Points

1.

Professor Kaoru Ishikawa created Cause & Effect

Analysis in the 1960s. The technique uses a diagram-based approach for thinking

through all of the possible causes of a problem. This helps you to carry out a

thorough analysis of the situation.

2.

There are four steps to using Cause and Effect

Analysis.

Identify the problem.

Work out the major factors involved.

Identify possible causes.

Analyze your diagram.

Appreciation (Situational)

Understanding the Full Implications of a Fact

Appreciation

Squeeze out as much information as you can, by

appreciating the situation accurately.

Sometimes we're given a piece of information that

seems straightforward, only to find out later that more was going on than we

thought. As a result, we're then

unprepared to deal with the consequences.

One way to deal with these situations is by using

Appreciation. This is a simple but

powerful technique for extracting the maximum amount of information possible

from a simple fact or statement.

About

Appreciation

Appreciation helps us uncover factors that we might

have ordinarily missed, and it can be very useful for brainstorming solutions

to problems.

It was originally developed by the military to help

commanders gain a comprehensive understanding of any fact, problem or situation

that it was faced with in battle.

Using Appreciation starts with a fact, you first ask

the question "So what?" – in other words, what are the implications

of that fact? Why is this fact important?

You then continue asking that question until you

have drawn all possible conclusions from it.

Uses

1.

Appreciation is similar to the 5 Whys technique. The

major difference is that it is often used to get the most information out of a

simple fact or statement, while the 5 Whys is specifically designed to drill

down to the root of a problem.

2.

also use Appreciation in conjunction with Root Cause

Analysis or Cause and Effect Analysis to help you gain a better understanding

of the impact of possible solutions.

Note:

Bear in mind that Appreciation can restrict you to

one line of thinking. Repeat the

Appreciation process several times over to make sure that you've covered all

bases.

Key

Points

1.

Appreciation was originally developed by the

military to give leaders a better understanding of a fact, statement or problem

that they were faced with.

2.

You use Appreciation by asking "So what?"

repeatedly. This helps you to extract all important information implied by a

fact.

3.

Consider using other problem solving techniques with

Appreciation, to make sure that you're not limited to one line of thinking.